Application:

- For long work pieces (8 to 30 metres in length), which require machining operations only at the two ends of the work piece

- Typical usage is for milling, drilling and tapping I-beam & H-beam structural steel

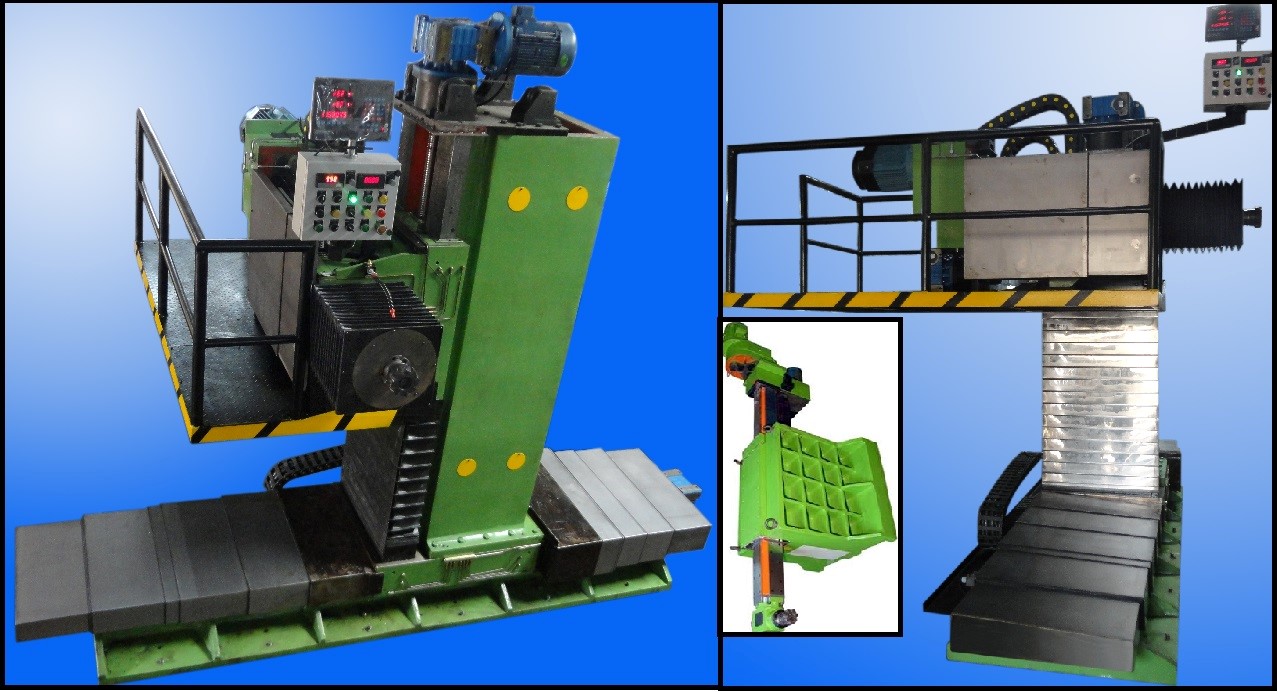

Basic Design:

- Rigid, heavily ribbed, stress relieved grey cast iron structure conforming to IS:210

- Machine bed, telescopic sliding guide way with bellow cover protection, vertical single column moving on machine bed

- All the slides are driven by lead screw, coupled to worm reduction gear boxes and AC induction motor.

- Slides are made of cast iron sliding surface and driven through either lead screw / phosphor bronze nut OR rolled ball screw. The bottom slide moves is in longitudinal direction.

- The column carries the cross travel guide way with bellow protection, spindle head and drive. A Milling Head is mounted on top of the slide. The rotating spindle carries the tool holder and milling cutter.

|

Machining Capabilities |

|||

|

DRILLING |

MILLING |

TAPPING |

FACING |

|

X axis – Longitudinal Slide |

Y axis – Vertical Slide |

||

|

Stroke |

1000 to 3000 mm |

Stroke |

300 to 1000 mm |

|

Rapid traverse |

1000 mm/min |

Rapid traverse |

1000 mm/min |

|

Feed Rate |

40-1000 mm/min (step-less) AC Drive |

Feed Rate |

40-1000 mm/min (step-less) AC Drive |

|

Motor Power |

2.2 kW |

Motor Power |

2.2 kW |

|

Z axis – Cross/Ram slide |

Milling Head |

||

|

Stroke |

300 to 600 mm |

Milling Head |

Model MHR-5 / MHR-10 / MHR-20 |

|

Rapid traverse |

1000 mm/min |

Power |

3.7 to 11 kW |

|

Feed Rate |

40-1000 mm/min (step-less) AC Drive |

Tool locking system |

Manual through draw-bar OR Automatic arbour clamping / de-clamping |

|

Motor Power |

2.2 kW |

Drive |

VFD Interfaced Spindle Motor |