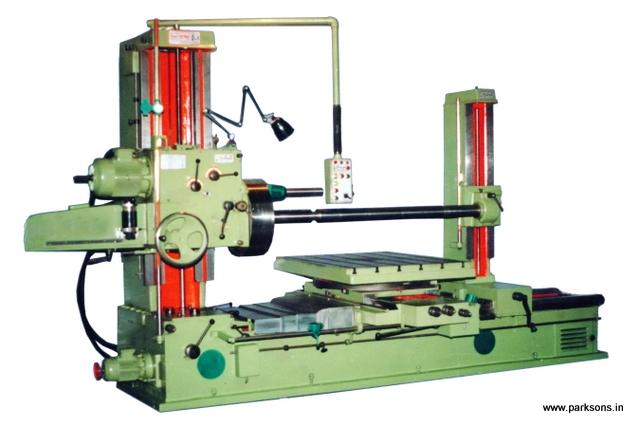

Description:

- Fixed Column, built-in Rotary Indexing Table which also travels transversally

- Wide range of spindle speeds & gearbox feeds allow for high output with the use of high-speed steel and carbide tools

- Hardened & ground alloy steel spindle

- Facing Head coupled with main spindle facilitates large diameter boring and facing operations

- Auto Rapid Travel for Facing Slide for improved productivity

- Independent motors for Spindle & Motor with Centralized Pendant Control for easy operation

- Telescopic Steel Covers for Guide ways to prevent ingress from damaging the guide ways

- Turcite B-Lining on all guide ways for smooth operation

- Machine is provided with Boring Bar and Support, Five Limit Switches

Specifications: (In mm unless specified otherwise)

| Model | HBM-65 | HBM-80 | HBM-100 | HBM-110 | HBM-125 |

| Spindle Diameter | 65 | 80 | 100 | 110 | 125 |

| Spindle Travel | 410 | 510 | 510 | 510 | 600 |

| Rotary Table | 880 x 1015 | 900 x 1105 | 1030 x 1375 | 1100 x 1450 | 1200 x 1500 |

| Facing Head Diameter | 450 | 505 | 555 | 600 | 650 |

| Spindle Speed | 20-300 RPM | 15-300 RPM | 15-300 RPM | 15-250 RPM | 15-250 RPM |

| Main Motor | 2.2 kW | 3.7 kW | 5.5 kW | 7.5 kW | 9.5 kW |

- Bigger main motor available, if required

- Bigger Rotary Table available, if required

Accuracy: As per Grade-I limits of Dr. G. Schlesinger’s Acceptance Test

- Quality of bore attainable H-7

- Ovality in bore: 0.01mm

- Position accuracy of Rotary Table: 0.02mm

Application:

- Horizontal boring, drilling and surface milling

- Reaming, turning and facing using facing head slide

- Machining bores in gearboxes & machine bodies

- 30º taper boring for 100-300 mm diameter using Taper Boring Attachment

- Inch threading (5-128) and Metric threading (0.28-7.5) using Threading Attachment

- 360º vertical milling up to 600mm depth using Vertical Milling Attachment

Accessories:

Digital Read Out, Threading Attachment, Vertical Milling Attachment, Taper Boring Attachment